Two-stage permanent magnet frequency conversion air compressor is a kind of high-efficiency and energy-saving air compression equipment.

Working Principle

It adopts two-stage compression technology to gradually increase the gas pressure through two compression stages. In the first stage of compression, the air is initially compressed to a certain pressure, and then it enters the intermediate cooler for cooling to reduce the temperature before entering the second stage of compression to finally achieve the required high pressure output.

Permanent magnet frequency conversion technology, on the other hand, makes use of permanent magnet synchronous motors to automatically adjust the motor speed according to the actual air demand, thus achieving precise air volume control. Compared with the traditional fixed-frequency air compressor, it can effectively avoid frequent starting and stopping and no-load operation, which greatly reduces energy consumption.

Product features

High efficiency and energy saving: The combination of two-stage compression and permanent magnet frequency conversion technology makes the compressor able to save energy to the maximum extent during operation. Compared with single-stage compressor, two-stage compression can reduce energy consumption by about 15% to 30%. Meanwhile, the high efficiency of the permanent magnet synchronous motor further improves the overall energy efficiency.

Stable and Reliable: Adopting advanced design and manufacturing process to ensure stable operation of the equipment. The permanent magnet motor does not require excitation current, which reduces the loss and heat generation of the motor and prolongs the service life of the motor. Moreover, the intermediate cooling in the two-stage compression process can effectively reduce the temperature of compressed air and reduce the damage to the equipment.

Intelligent control: Equipped with intelligent control system, it can monitor the running status of the equipment in real time and adjust the parameters automatically to achieve unattended operation. Users can conveniently operate and manage the equipment through touch screen or remote control.

Low noise: optimised structural design and sound insulation measures make the air compressor run with low noise, providing users with a quiet working environment.

Convenient maintenance: the structure of the equipment is simple and easy to maintain. Regular maintenance and inspection can ensure the long-term stable operation of the equipment.

Application field

Two-stage permanent magnet frequency conversion air compressor is widely used in industrial production, manufacturing, automobile maintenance, building construction and other fields. It can provide stable and reliable compressed air source for pneumatic tools, spraying equipment, automated production lines and so on.

In a word, two-stage permanent magnet frequency conversion air compressor has become the ideal choice for modern air compression equipment with its features of high efficiency and energy saving, stability and reliability, intelligent control and so on.

Two-stage permanent magnet frequency conversion air compressor is a kind of high-efficiency and energy-saving air compression equipment.

Working Principle

It adopts two-stage compression technology to gradually increase the gas pressure through two compression stages. In the first stage of compression, the air is initially compressed to a certain pressure, and then it enters the intermediate cooler for cooling to reduce the temperature before entering the second stage of compression to finally achieve the required high pressure output.

Permanent magnet frequency conversion technology, on the other hand, makes use of permanent magnet synchronous motors to automatically adjust the motor speed according to the actual air demand, thus achieving precise air volume control. Compared with the traditional fixed-frequency air compressor, it can effectively avoid frequent starting and stopping and no-load operation, which greatly reduces energy consumption.

Product features

High efficiency and energy saving: The combination of two-stage compression and permanent magnet frequency conversion technology makes the compressor able to save energy to the maximum extent during operation. Compared with single-stage compressor, two-stage compression can reduce energy consumption by about 15% to 30%. Meanwhile, the high efficiency of the permanent magnet synchronous motor further improves the overall energy efficiency.

Stable and Reliable: Adopting advanced design and manufacturing process to ensure stable operation of the equipment. The permanent magnet motor does not require excitation current, which reduces the loss and heat generation of the motor and prolongs the service life of the motor. Moreover, the intermediate cooling in the two-stage compression process can effectively reduce the temperature of compressed air and reduce the damage to the equipment.

Intelligent control: Equipped with intelligent control system, it can monitor the running status of the equipment in real time and adjust the parameters automatically to achieve unattended operation. Users can conveniently operate and manage the equipment through touch screen or remote control.

Low noise: optimised structural design and sound insulation measures make the air compressor run with low noise, providing users with a quiet working environment.

Convenient maintenance: the structure of the equipment is simple and easy to maintain. Regular maintenance and inspection can ensure the long-term stable operation of the equipment.

Application field

Two-stage permanent magnet frequency conversion air compressor is widely used in industrial production, manufacturing, automobile maintenance, building construction and other fields. It can provide stable and reliable compressed air source for pneumatic tools, spraying equipment, automated production lines and so on.

In a word, two-stage permanent magnet frequency conversion air compressor has become the ideal choice for modern air compression equipment with its features of high efficiency and energy saving, stability and reliability, intelligent control and so on.

A heat exchanger is a highly efficient device for transferring heat between different media.

Principle of operation

The heat exchanger uses two or more fluids of different temperatures to transfer heat through a solid wall. The high-temperature fluid transfers heat to the wall, and the wall transfers heat to the low-temperature fluid, so that the low-temperature fluid is heated and the high-temperature fluid is cooled. According to the different ways of heat transfer, heat exchangers can be divided into three types: inter-wall, hybrid and thermal storage. Of these, the inter-wall heat exchanger is the most common type, which separates the two fluids by a solid wall, avoiding direct contact between the fluids.

Product features

High-efficiency heat transfer: adopting advanced heat transfer technology and optimised structural design, it can realise efficient heat transfer and improve the efficiency of energy use.

Compact structure: small volume, occupies less space, easy to install and maintain.

Strong adaptability: can be designed and selected according to different fluid properties, temperature, pressure and other conditions to meet the needs of various working conditions.

Good corrosion resistance: corrosion-resistant materials can be used to extend the service life of the equipment.

Safe and reliable operation: it has good sealing and pressure resistance to ensure the safety and reliability of the equipment in the process of operation.

Application Fields

HVAC: Used for heat exchange in heating, ventilation and air-conditioning systems to improve energy efficiency.

Industrial production: in chemical, petroleum, pharmaceutical, food and other industries, for heating, cooling, condensation, evaporation and other processes in the heat transfer.

Energy field: in thermal power plants, nuclear power plants and other energy facilities, for waste heat recovery, energy conversion, etc.

Transportation: in automobiles, ships, aircraft and other means of transport, for engine cooling, air-conditioning systems and other heat exchange.

Environmental protection field: used for heat recovery and utilisation in the process of sewage treatment, waste gas treatment and so on.

In short, heat exchanger as an important energy transfer equipment, in various fields play an important role. With the continuous progress of science and technology, the performance and efficiency of the heat exchanger will continue to improve, making greater contributions to the realisation of energy saving, emission reduction and sustainable development.

In today's highly competitive vacuum pump market, Hylein vacuum pumps stand out for their superior performance. With energy savings of approximately 50 % compared to other technologies, Hylein vacuum pumps are undoubtedly one of the most energy-efficient permanent magnet variable speed screw vacuum pumps on the market today. When we look at traditional oil-lubricated rotary vane pumps, water ring pumps and other technologies, we find that they have the obvious shortcomings of lower mechanical efficiency and higher costs. In the process of vacuum application, nearly 90% of electrical energy is usually converted into heat, which not only causes a large amount of energy waste, but also increases the operating costs of enterprises.

Hylein's full range of screw vacuum pumps are equipped with an integrated energy recovery system, which offers powerful advantages. The system is capable of converting up to 75 % of the electrical energy input into heat without any adverse effects on the equipment in the process. This means that by utilising the energy recovery system effectively, companies can make significant savings on their energy costs and invest their limited capital in more valuable business development. At the same time, the high return on investment makes HELIN vacuum pumps a smart choice for many companies. Whether in industrial production, scientific research experiments or other fields, Hylein vacuum pumps bring tangible benefits to users with its high efficiency, energy saving and reliability. It is not only an advanced equipment, but also an important force to promote the sustainable development of the industry.

In today's highly competitive vacuum pump market, Hylein vacuum pumps stand out for their superior performance. With energy savings of approximately 50 % compared to other technologies, Hylein vacuum pumps are undoubtedly one of the most energy-efficient permanent magnet variable speed screw vacuum pumps on the market today. When we look at traditional oil-lubricated rotary vane pumps, water ring pumps and other technologies, we find that they have the obvious shortcomings of lower mechanical efficiency and higher costs. In the process of vacuum application, nearly 90% of electrical energy is usually converted into heat, which not only causes a large amount of energy waste, but also increases the operating costs of enterprises.

Hylein's full range of screw vacuum pumps are equipped with an integrated energy recovery system, which offers powerful advantages. The system is capable of converting up to 75 % of the electrical energy input into heat without any adverse effects on the equipment in the process. This means that by utilising the energy recovery system effectively, companies can make significant savings on their energy costs and invest their limited capital in more valuable business development. At the same time, the high return on investment makes HELIN vacuum pumps a smart choice for many companies. Whether in industrial production, scientific research experiments or other fields, Hylein vacuum pumps bring tangible benefits to users with its high efficiency, energy saving and reliability. It is not only an advanced equipment, but also an important force to promote the sustainable development of the industry.

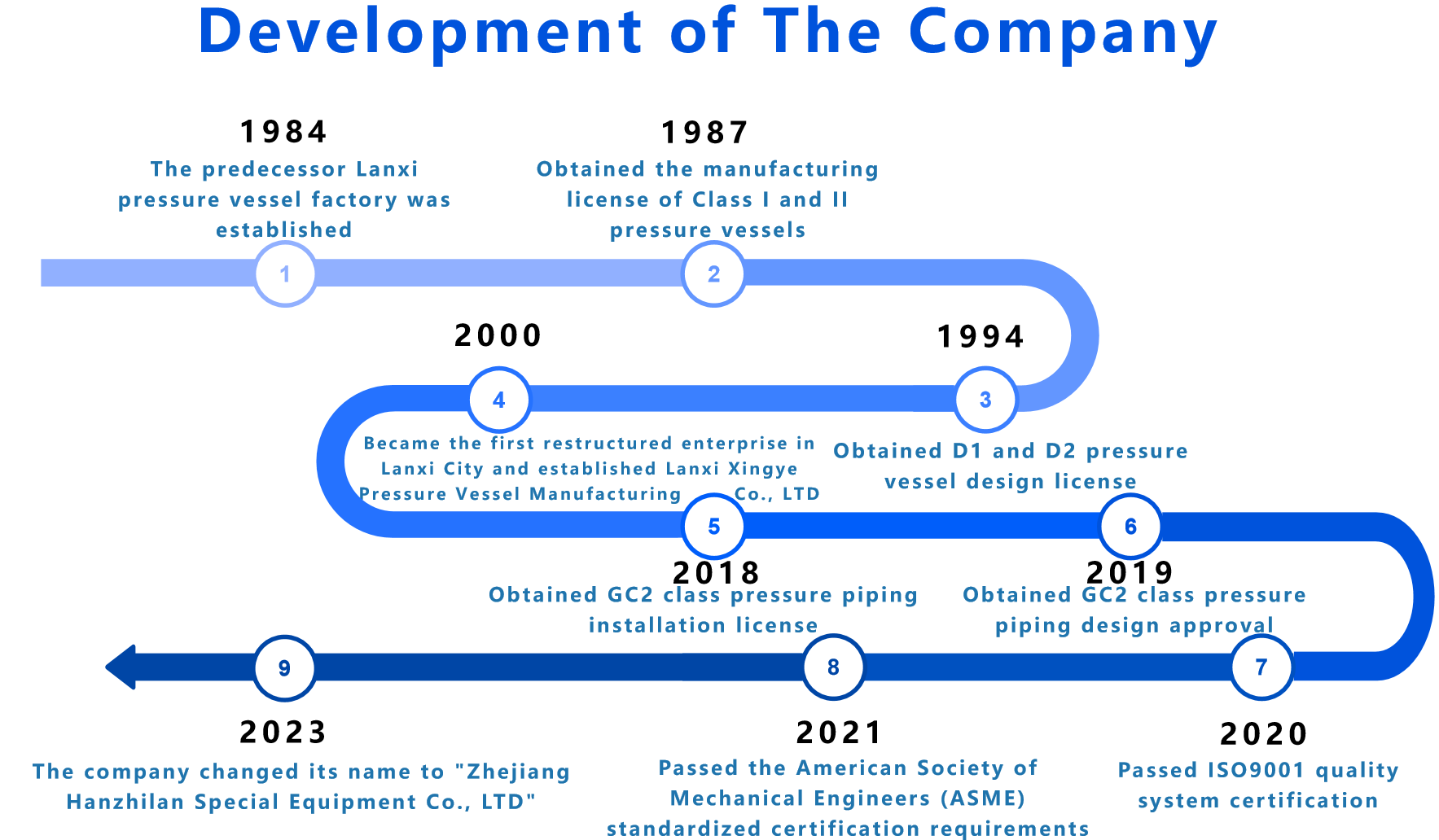

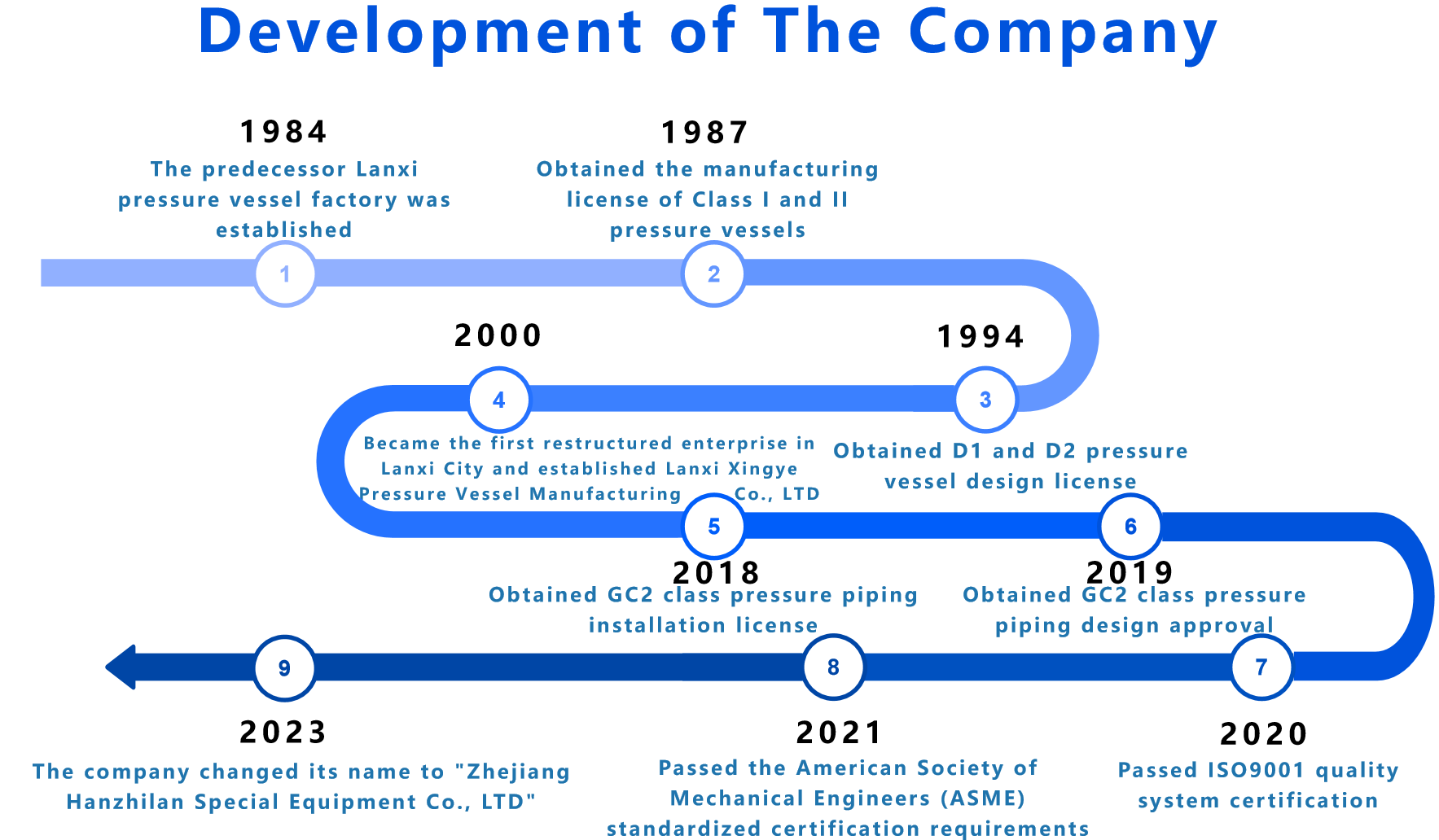

Founded in 1984, Zhejiang Branch of Guangzhou Hanzhilan Energy and Environmental Technology Co., Ltd. obtained the first and second class pressure vessel manufacturing license in 1987, the company obtained the GC2 level pressure pipeline installation license in 2018, the first GC2 level pressure pipeline design license in 2019, and the ISO9001 quality system certification in 2020. In 2021, through the American Society of Mechanical Engineers (ASME) standardization certification requirements, is a collection of scientific research, design, production, sales as one of the national high-tech enterprises!

Founded in 1984, Zhejiang Branch of Guangzhou Hanzhilan Energy and Environmental Technology Co., Ltd. obtained the first and second class pressure vessel manufacturing license in 1987, the company obtained the GC2 level pressure pipeline installation license in 2018, the first GC2 level pressure pipeline design license in 2019, and the ISO9001 quality system certification in 2020. In 2021, through the American Society of Mechanical Engineers (ASME) standardization certification requirements, is a collection of scientific research, design, production, sales as one of the national high-tech enterprises!

Founded in 1984, Zhejiang Branch of Guangzhou Hanzhilan Energy and Environmental Technology Co., Ltd. obtained the first and second class pressure vessel manufacturing license in 1987, the company obtained the GC2 level pressure pipeline installation license in 2018, the first GC2 level pressure pipeline design license in 2019, and the ISO9001 quality system certification in 2020. In 2021, through the American Society of Mechanical Engineers (ASME) standardization certification requirements, is a collection of scientific research, design, production, sales as one of the national high-tech enterprises!

Founded in 1984, Zhejiang Branch of Guangzhou Hanzhilan Energy and Environmental Technology Co., Ltd. obtained the first and second class pressure vessel manufacturing license in 1987, the company obtained the GC2 level pressure pipeline installation license in 2018, the first GC2 level pressure pipeline design license in 2019, and the ISO9001 quality system certification in 2020. In 2021, through the American Society of Mechanical Engineers (ASME) standardization certification requirements, is a collection of scientific research, design, production, sales as one of the national high-tech enterprises!